When Panduit introduced the VeriSafeTM Absence of Voltage Tester (AVT) six years ago, it was a major innovation in electrical safety. It meets NFPA 70E and CSA Z462* best practice for testing absence of voltage, and enables your facility to operate safer, smarter, and more efficiently. However, as is the case with any new technology, it’s not been without its skeptics. In this article, with Panduit’s help, we’re going to dispel the three most common misconceptions about Absence of Voltage Testers and explain why an AVT is not just a good alternative to portable test instruments, but a superior one.

Myth #1: AVTs Don’t Perform as Well as Portables or Portals

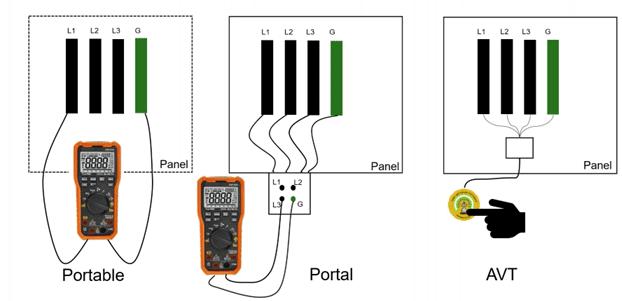

People love to make comparisons. But let’s look at portables, portals, and AVTs side by side.

Portables require an open cabinet, potentially leaving the user exposed to hazards. There are also opportunities to misidentify conductors and choose the wrong settings. Finally, the lack of contacts can make it a challenge to obtain an accurate reading.

Portals enable troubleshooting voltage with the door remaining closed, but they also add several failure points to the system. The addition of failure points on a life safety process like absence of voltage testing is risky. With Portals, you’re prone to losing contact with the conductor and susceptible to high impedance device failures. They’re also much easier to tamper with, accidentally or intentionally, and the local authority having jurisdiction (AHJ) will often require overcurrent protection for test portals with leads longer than 12 inches in order to meet NEC or UL 508A requirements. In this case, you would not be testing the conductor or circuit part, but the line side of a fuse.

The first generation of VeriSafe AVTs ran the risk of losing contact with the conductor if the leads weren’t tied off as indicated in the manufacturer’s instructions. While this is eliminated when following the installation instructions and commissioning checklist, this has been corrected in VeriSafe 2.0, leaving users vulnerable to none of the risks the other two methods expose them to. And as we’ll detail in Myth #2, there’s a battery of tests the AVT needs to pass to display the green light of safety.

Myth #2: You Can’t Trust “Just Pushing a Button”

It’s true, using an AVT is as simple as pushing a button for the user. But what you can’t see is the process that button push triggers and everything that happens in the 10 seconds between the button being pushed and the light turning green. So let’s talk through it:

It’s true, using an AVT is as simple as pushing a button for the user. But what you can’t see is the process that button push triggers and everything that happens in the 10 seconds between the button being pushed and the light turning green. So let’s talk through it:

- First it verifies there’s available power to run the test.

- Next, the system validates the internal circuitry.

- Then, it validates that the AVT can measure 3V accurately.

- Next, it verifies the installation.

- Only after all four steps above are satisfied, the AVT tests for known voltage sources (L-L and L-G for all phases).

What’s more? If all of the above pass, the system repeats all five steps a second time. There’s only one way to get a green light on the VeriSafe AVT button. It will only display if the tests are all passed completely, twice in a row.

We’ll talk more about trust in our next myth. But to reduce the performance of AVTs down to the push of a button is a mistake. There are a lot of buttons we push in life that set into motion a series of technical processes that we may not understand the science of. But we still trust them. When you apply pressure to your brake pedal, you trust that the anti-lock braking system will do what it’s supposed to do and keep you safe. When you push a button in an elevator, you trust the unit to safely transport you to the top floor of a 20-story building.

The value of an AVT is not the button push. It’s what happens after the button gets pushed.

Myth #3: AVTs Aren’t Reliable

The Oxford Languages dictionary defines reliable as “consistently good in quality or performance; able to be trusted.” That’s a two-part definition. The first part is objective and measurable. There are standards in the electrical industry that determine if something is consistently good in quality or performance.

UL 1436 is a standard for outlet circuit testers and similar indicating devices. Section 12 of UL 1436 defines the requirements of how an AVT must function, what testing it must undergo and what standards it must achieve. In order for an AVT to be UL 1436 listed, it must also meet IEC 61508 and be SIL3 (Safety Integrity Level) rated. UL 1436 also requires AVTs to meet UL 61010-1 and UL 61010-2-030, which just adds more to the list of what an AVT must be designed and developed against, but let’s focus on IEC 61508 and the SIL3 ratingSIL3 rating measures the number of hours of runtime before a user could expect a failure. VeriSafe’s AVT would need to run once an hour for 1,142 to 11,416 years before failing to green according to its SIL3 rating. Of course, the products haven’t been around that long. But it’s valid to note Panduit has not seen one failure to green in the six years VeriSafe has been on the market.

UL 1436 is a standard for outlet circuit testers and similar indicating devices. Section 12 of UL 1436 defines the requirements of how an AVT must function, what testing it must undergo and what standards it must achieve. In order for an AVT to be UL 1436 listed, it must also meet IEC 61508 and be SIL3 (Safety Integrity Level) rated. UL 1436 also requires AVTs to meet UL 61010-1 and UL 61010-2-030, which just adds more to the list of what an AVT must be designed and developed against, but let’s focus on IEC 61508 and the SIL3 ratingSIL3 rating measures the number of hours of runtime before a user could expect a failure. VeriSafe’s AVT would need to run once an hour for 1,142 to 11,416 years before failing to green according to its SIL3 rating. Of course, the products haven’t been around that long. But it’s valid to note Panduit has not seen one failure to green in the six years VeriSafe has been on the market.

That takes care of quality and performance. Now we’re left with trust. Trust is more subjective. It’s earned and not given. It can’t be forced, and it comes with time. It’s likely that a fair number of people opted for the old reliable staircase for a while even after the invention of elevators. We get it. This technology is transforming electrical safety. Panduit is confident in the product and willing to commit to earning the trust of their customers over time.

Have Questions About Panduit’s VeriSafe AVT?

When it comes to new technology, it’s perfectly understandable to have apprehension or questions. Thankfully, your Account Manager or local Agilix branch is your connection to our in-house team of experts here to answer them. Reach out to take the first steps toward a safer working environment for your team.