Thermography Scans for Preventive Maintenance

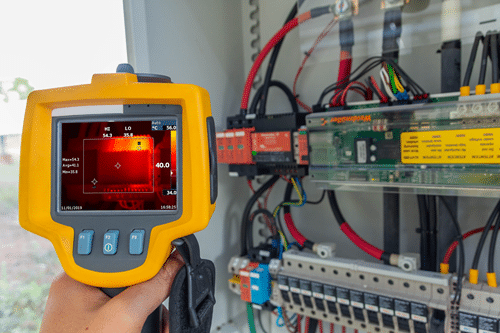

Excessive heat is a leading cause of equipment failure. But too often, by the time heat issues are identified, it’s too late. That’s why Agilix Solutions offers thermography services. Using a special heat-sensing camera, we’re able to identify abnormal heat issues that would otherwise be difficult to detect.

After we perform a thermographic survey, our thermography experts deliver a complete report that details hot points in any system, provides info on ambient temperature and specific temperature, shows which phase of operation is producing excessive heat, and details possible causes.

Where Can Thermography be Used?

Many people think of thermography strictly as an electrical service. And while we do electrical inspections, there are a variety of applications for thermography services:

- Electrical

- Identify deteriorated connections

- Find three phase unbalance and overloads

- Pinpoint hot or cool anomalies in substations

- Motors

- Compare bearing and housing temperature against known acceptable thermal values

- Use exterior thermal casing gradient as an indicator of internal temperature

- Measure heat in gearboxes to identify lubrication issues

- Pipes – look for temperature anomalies to find leaks

- Ducts – identify blockages and leaks in ventilation systems

- Valves and Traps – Insure proper operation

- Tanks and Vessels – Check liquid and gas levels, and identify settling or blocking of tubes

- Roofs – Detect leakage and ensure proper seals

- Insulation Defects – Find gaps in wall and ceiling insulation in rooms or building envelopes

- Refrigerated Areas – Ensure proper seals

- Hydraulic Systems – Identify potential failure points through temperature anomalies

- IT/Computer Rooms – Identify additional cooling needs where hotspots exist

We recommend customers perform a thermography audit at least once a year, whether they are having heat-related issues or not. We offer more frequent services to help our customers prevent disaster and extend the life of their equipment.

Why Choose Agilix Solutions’ Thermography Services?

There are three primary reasons to choose Agilix Solutions to perform your thermography audit:

- Consistency – Some customers purchase a thermographic camera with the intent to perform their own thermography audits. Often, it’s a low priority that gets forgotten. When you partner with Agilix Solutions, identifying heat issues in your equipment will be a “set it and forget it” task you won’t need to worry about.

- Affordability – Agilix Solutions’ thermography services are competitively priced to ensure you receive maximum value for your investment.

- Safety – Heat related equipment problems pose all sorts of potential safety risks. Our team is trained to conduct safe inspections using the proper PPE for each thermographic audit.

Agilix Solutions’ thermography team is certified through The Snell Group, a respected thermographic equipment and training organization. We deploy trained personnel using state-of-the-art equipment to ensure accuracy you can rely on. Contact us today to schedule your next thermographic audit and experience the Agilix Solutions difference.

Thermal Cooling Audit for Electrical Enclosures

With summer heat coming soon, proactive identification of critical hot spots can mean the difference between equipment failure and cool running. Heat [...]

Read MoreUse Thermography to Stay Ahead of the Maintenance Curve in Your Facility

Thermography and thermal imagery have been used for detection purposes since the 1950s. It has a wide variety of capabilities in facility management. [...]

Read MoreStrategies for Managing your Inventory of Critical Machine Spare Parts

If you work in manufacturing or on a commercial jobsite, you’ve likely found yourself in the middle of a project when you realized that you don’t [...]

Read More