Today’s industrial landscape is moving faster than ever before. In this environment, unplanned downtime is more than just an inconvenience, it’s a direct and powerful blow to a company’s bottom line. Maintenance managers and operations executives are under increasing pressure to develop strategies to keep machinery running efficiently, reduce operational costs, and increase asset longevity.

Rockwell Automation’s PowerFlex® drives equipped with TotalFORCE® technology offer a transformative solution to these challenges, particularly through their advanced predictive maintenance capabilities.

This article explores how TotalFORCE technology enhances predictive maintenance to support smarter, more reliable industrial operations.

What Is TotalFORCE® Technology?

TotalFORCE® is Rockwell Automation’s proprietary motor control technology, available in the PowerFlex® 755TS, 755TL, 755TR, 755TM, and 6000T drive families. The TotalFORCE name encompasses a suite of capabilities that blend real-time operational intelligence, adaptive control, and predictive analytics to elevate machine performance.

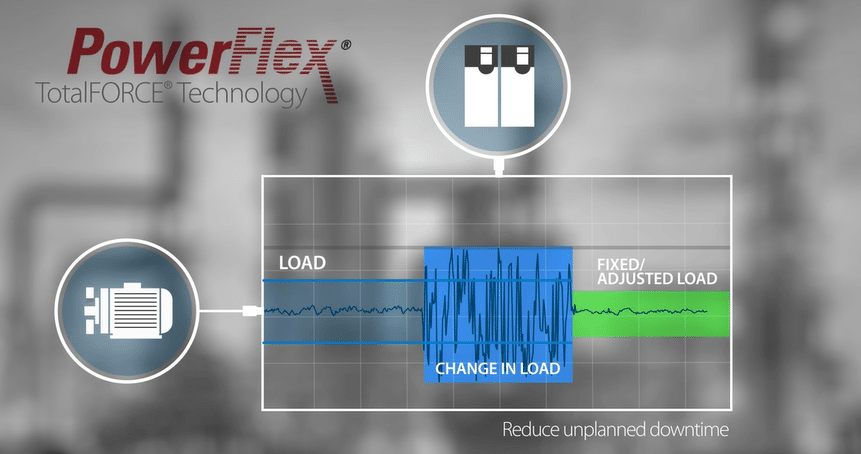

Unlike traditional drives that operate reactively, TotalFORCE drives are proactive. They sense changes in the system, adapt accordingly, and provide real-time insights to help detect potential issues before they disrupt operations. This blend of adaptability and intelligence is the foundation of predictive maintenance and sets a new standard for industrial automation.

TotalFORCE® Predictive Maintenance: The Heart of Smarter Operations

Predictive maintenance enabled by TotalFORCE technology involves continuous monitoring of drive and motor performance parameters such as heat levels, component runtime hours, blown fuses or internal faults, mechanical stress or wear, and electrical signature anomalies.

Using real-time diagnostics, PowerFlex drives go beyond reporting issues. They anticipate them. This allows maintenance teams to address problems before they result in costly downtime.

For example, imagine a drive that can alert technicians to excessive heat buildup or warn when a component is nearing the end of its operational life. This foresight helps in planning maintenance schedules effectively, ensuring equipment is serviced only when necessary, rather than on a rigid calendar-based routine.

What Could TotalFORCE® Enable in Your Operations?

Rockwell Automation’s PowerFlex drives with TotalFORCE technology represent a leap forward in predictive maintenance. By combining real-time data monitoring, intelligent analytics, and adaptive control, these drives deliver beyond just motor control. They offer reality-informed insight, foresight, and control over operational outcomes.

Rockwell Automation’s PowerFlex drives with TotalFORCE technology represent a leap forward in predictive maintenance. By combining real-time data monitoring, intelligent analytics, and adaptive control, these drives deliver beyond just motor control. They offer reality-informed insight, foresight, and control over operational outcomes.

Learn more about putting TotalFORCE to work in your plant operations today. Reach out to your Account Manager or contact your local Agilix branch to start the discussion. Let’s work together to strengthen your uptime strategy.