As manufacturers and OEMs face increasing pressure to move faster, scale globally, and maintain consistency across operations, one challenge continues to surface: enclosure standardization.

Design teams want flexibility. Operations teams want reliability. Procurement wants simplicity, and global organizations want a solution that works everywhere without redesigns, requalification, or supply chain complexity.

At Agilix Solutions, we see this tension every day. It is a big reason why we recommend nVent HOFFMAN IEC-rated enclosures and accessories as a foundational solution for customers looking to simplify design, accelerate build time, and support global deployment without compromise.

More Than an Enclosure: A Platform for Efficiency

Many enclosure solutions solve one problem well but introduce others. Some are easy to design with but difficult to assemble. Others are robust but inflexible, and many fall short when customers try to standardize across regions.

HOFFMAN IEC enclosures take a different approach. Rather than treating enclosures as one-off components, nVent has built a modular, globally consistent enclosure platform that supports both OEM and end-user requirements from design through lifecycle.

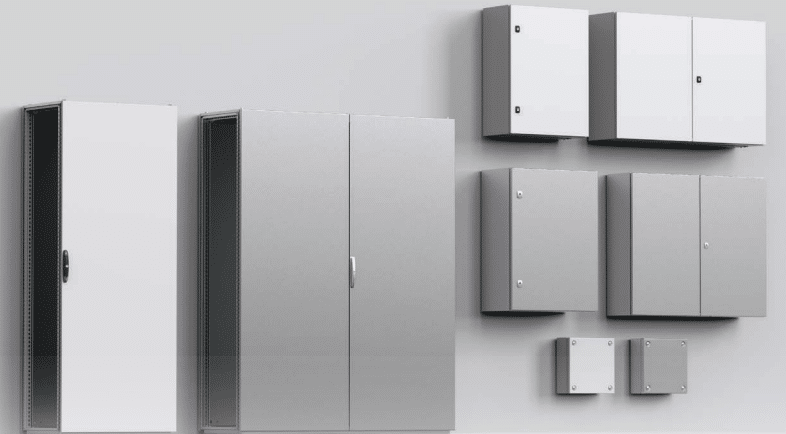

Available in mild steel and stainless steel, HOFFMAN IEC offerings include modular floor-standing enclosures, wall-mounted enclosures, and terminal boxes, supported by a comprehensive portfolio of accessories. This flexibility allows customers to apply the same enclosure strategy across machine-level, line-level, and facility-level applications without starting from scratch each time.

Solving the Global Standardization Problem

For organizations operating across multiple regions, enclosure standardization can quickly become a liability. Different part numbers, regional variants, and local substitutions add cost, risk, and complexity.

HOFFMAN IEC enclosures address this head-on with single, universal part numbers that can be deployed globally. That means:

- Fewer SKUs to manage

- Simplified procurement and spares strategies

- Consistent designs across plants and machines

- Faster replication of proven solutions

For OEMs, this reduces engineering effort and shortens time to market. For manufacturers, it improves maintainability and lowers total cost of ownership.

Faster Assembly Where It Matters Most

Panel build labor is increasingly scarce and expensive. Small inefficiencies compound quickly when multiplied across machines or production lines.

One of the standout differentiators of HOFFMAN IEC enclosures is patented Click-In technology. This tool-free mounting system allows accessories to snap securely into place, reducing assembly time by up to 14 minutes when baying floor-standing enclosures.

That time savings shows up directly on the shop floor as:

- Faster panel builds

- Reduced rework

- More consistent assembly quality

In comparison to traditional bolt-on approaches used by many enclosure brands, Click-In technology removes friction from the build process without sacrificing strength or reliability.

Design Once, Deploy Anywhere

Engineering efficiency doesn’t stop at physical assembly. In today’s environment, digital design tools play a critical role in speed and accuracy.

nVent HOFFMAN supports this with a robust digital part library, offering drawings in a wide range of formats compatible with nearly any major design platform. Engineers can quickly integrate enclosures and accessories into their layouts with confidence, eliminating guesswork and reducing design cycles.

Combined with interchangeable accessories that work across wall-mounted and floor-standing enclosures, this creates a highly adaptable system. Designs can evolve, scale, or shift configurations without forcing a complete redesign. That’s something many competitive enclosure systems struggle to support.

A Smarter Enclosure Strategy Starts Here

In a world where speed, standardization, and scalability define competitive advantage, enclosures can no longer be an afterthought. HOFFMAN IEC enclosures stand out for quality, but also because they solve real problems across design, build, deployment, and lifecycle.

When paired with Agilix Solutions’ application expertise and system-level perspective, they become a powerful tool for manufacturers and OEMs looking to do more with less friction.

If you’re evaluating enclosure strategies for your next project or looking to standardize across operations, your Agilix Solutions Account Manager should be your first call. Reach out or contact your nearest local branch to discuss how HOFFMAN IEC Enclosures can be applied for maximum impact in your project.