Agilix Solutions is a Rockwell Automation authorized distributor of Allen-Bradley products and technologies.

Being an authorized distributor of Rockwell Automation allows us to provide automation sophistication, electrical supply chain management, and world-class local support. You receive comprehensive management of your electrical supply inventory, extensive training for your people, and quantifiable cost savings. This service provides you with the available time to focus on your core competencies and sharpen your competitive edge.

Not currently registered for a my.goAgilix.com online account, click here.

Note: Agilix Solutions is only authorized to distribute Allen-Bradley, Rockwell Software and Rockwell Automation products in select geographic areas. If you need immediate assistance or do not see the specific items you need, please contact us toll free at 800-333-3122.

Featured Products

Rockwell Automation News & Updates

Enhance Your Team’s Skills with Professional Training from Agilix Solutions

You’ve invested in the latest industrial technology to modernize your plant and ensure the efficiency of your operations. Have you invested enough [...]

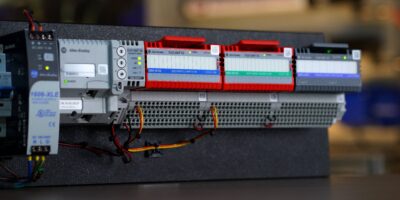

Read MoreArmorBlock 5000 & FLEX 5000: Distributed I/O Solutions for Modern Production Environments

Rockwell Automation’s products represent one of the most extensive, impressive, and diverse collections of I/O solutions on the market. In this art [...]

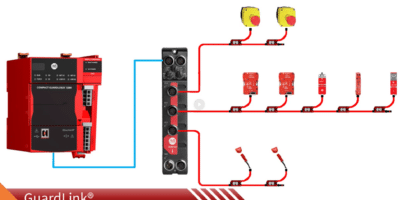

Read MoreRockwell Automation GuardLink® Technology Improves Machine Safety in Industrial Facilities

There’s no better time than June, National Safety Month, to introduce you to GuardLink® device level linking technology from Rockwell Automation. G [...]

Read MoreVideos

Rockwell Automation & Claroty: Comprehensive OT Security Solutions

Rockwell Automation Global Remanufacturing

Rockwell Automation Repair Services

Advantages of the New PowerFlex 755T

Products & Solutions

Transformative technology can differentiate your business. Explore the many products that can optimize your industrial operations.

Rockwell Automation’s broad range of quality products and technologies are designed to improve your productivity and flexibility, while enabling you to select the right product for your application.

Their approach to Smart, Safe, Sustainable Manufacturing will help you replace disparate slots of technology with an integrated, information-enabled plant and supply network.

Rockwell Automation offers a full range of machine control solutions, from cost-effective components to highly integrated systems. Each of these easily implemented solutions help you speed time to market and lower total cost to design, develop and deliver your machine.

Micro Control

Designed for large standalone machines, Rockwell Automation’s Micro Control System offers a cost-effective and customizable solution. Buy only the functionality you need to scale your control and use plug-in modules to personalize the system for your specific application. Plus, Micro Control helps to reduce development time and improve productivity with easy network connectivity at the convenience of the programming software.

Midrange Architecture System

Whatever your machine requirements are ― on safety, motion, operator interface ― Rockwell Automation has the control architecture that meets your needs. By standardizing on one single, scalable platform, you will achieve significant advantages with a right-sized control for machine performance and benefit from faster time to market with a single development environment.

Integrated Architecture

The Integrated Architecture system provides the foundation to efficiently and effectively drive plant-wide optimization, helping your company respond competitively to the economy and changes in consumer demand. Learn how Integrated Architecture improves productivity, promotes globalization, supports sustainability, cultivates innovation.

The Allen-Bradley industrial control components from Rockwell Automation deliver proven and predictable performance over the full life of the product, and help you to maximize the efficiency and performance of your machine or factory.

Complete Your Architecture

Control systems are susceptible to downtime from a wide range of issues. Allen-Bradley components are essential to solving common problems associated with your critical control applications, and in doing so, are key to enhancing the performance of your Integrated Architecture.

Connected Components

Connected Components combines a simple, powerful control core, a full suite of associated components and a dedicated set of class-leading application development tools.

Data exists everywhere throughout your operation. The Rockwell Automation FactoryTalk information software enables you to better visualize your production operations, analyze sources of inefficiencies, poor quality, or downtime, and provide standardized workflows and procedures to optimize production operations.

Manufacturing Operations Management

Manufacturing Operations Management provides standardized workflows to operators to ensure the highest possible production quality as well as regulatory compliance. In addition, it offers standard application library suites for common functions in the pharmaceutical, consumer packaged goods (CPG), and automotive industries.

Manufacturing Intelligence

Data exists everywhere throughout your operation. Manufacturing Intelligence strategies leverage a suite of reporting and analysis tools, interfaces and dashboards designed to deliver contextual, localized, role based.

Motor Control Devices are the building blocks of an efficient automation strategy, optimizing production and reducing costs. Rockwell Automation offers a wide range of flexible, robust products such as overload relays, contactors and starters and higher power control products such as low and medium voltage variable speed drives and motor control centers.

Many of the Rockwell Automation motor control devices easily plug and play into our Integrated Architecture system. This premier integration provides a single software tool for you to configure, control and diagnosis your machines. In addition, EtherNet/IP™, a common network for all your process and control equipment, can be seamlessly linked to the front office for fast access to information.

EtherNet/IP™ is the world’s leading open industrial ethernet network capable of handling the widest range of applications, including discrete, safety, motion, process and drive control.

Ethernet/IP and CIP Networks

EtherNet/IP™ is the world’s leading open industrial ethernet network capable of handling the widest range of applications, including discrete, safety, motion, process and drive control. EtherNet/IP delivers interoperable Ethernet products from more than 300 vendors, including Cisco, Schneider Electric, Omron, Bosch Rexroth and Rockwell Automation, providing more than 1,000 product lines and several million installed devices on EtherNet/IP.

Rockwell Automation is an established leader in industrial safety, helping reduce injuries and costs while improving productivity with functional safety solutions for machine, process, and electrical safety applications.

Safety Management

Proactive safety management using integrated, state-of-the-art technology delivers a measurable difference to plant performance and profitability.

Electrical Safety

See the measures you can take to reduce the risk of an arc flash occurrence, and reduce worker exposure to electrical hazards.

Process Safety

More than 40 years of experience providing process safety solutions to satisfy cost, safety integrity level (SIL 1,2 and 3), performance, and availability requirements including ESD, F&G, Turbine and Compressor, Combustion Control and CPC.

Machinery Safety

Innovative safety solutions can enhance the functional operation of machinery to help improve safety, productivity, and reduce waste.

You have assets to protect. Control systems, networks and software can all help defend against security threats and risks. It’s time to manage potential security threats and build a more secure industrial control system that meets your needs. Securing industrial assets requires a comprehensive security model based on a well-defined set of security policies. Rockwell Automation can help you construct secure industrial network designs and solutions with the implementation of secure switches, firewalls, routers, VPNs, and much more.

Network and Security Services capabilities from Rockwell Automation help you design, troubleshoot and verify that your system meets the level of security that is right for you, today and tomorrow.

Although security is merely one aspect of a complete, system-level controls solution, it remains an integral aspect to the Rockwell Automation controls philosophy and we remain committed to evolve security solutions to meet your needs.

Rockwell Automation offers quality Allen-Bradley components with over a century of time-tested reliability and durability. And when it comes to sensors, they have one of the broadest lines in the industry including Allen-Bradley limit switches, RFID, proximity, photoelectric, capacitive and ultrasonic sensors. Allen-Bradley sensors and switches set the standard for ruggedness, dependability and application flexibility.

Smart Sensors

An integrated Smart Sensor solution provides all the data required to create a comprehensive picture of the status of an enterprise at any particular moment. As integral components of The Connected Enterprise, Smart Sensors can also facilitate the introduction and operation of smart machines, for even greater efficiency and productivity. With Smart Sensors available for every possible parameter – from pressure to temperature, motion to distance, level to flow and many more – it is possible to sustain a comprehensive view of your process.

The Rockwell Automation visualization portfolio ranges from elec-tronic operator interface terminals to distributed client/server HMI and information software.

Human Machine Interface

FactoryTalk View provides robust and reliable functionality in an HMI solution that scales from a stand-alone, machine-level HMI to a distributed visualization solution. With FactoryTalk View, HMI challenges in process, batch and discrete applications are managed in a single software package that extends beyond the walls of your facility to deliver critical visibility on demand, im-proving the productivity of users at every level of your organization.

Rockwell Automation Training Courses

With a wide array of open enrollment courses, your employees will be equipped to realize the full capabilities of Rockwell Automation technologies.

In this ever-evolving world, Agilix Solutions understands your company needs to stay on top of the latest technologies and practices that will help you lower costs, increase production, drive efficiencies, and impact the bottom line. As a company committed to your success, the Agilix team provides the knowledge you need in the format most convenient for you. We offer both in-person and online training opportunities. If you have a specific training need, our team can also deliver custom or private training experiences tailored to your circumstances.

Local, In-Person Training

Events & Webinars

Take advantage of upcoming Rockwell Automation events to learn more about how you can use technology as a competitive advantage.

Use Technology as a Competitive Advantage

With the wide variety of technologies and services available, it can be difficult to identify the best solutions for your organization. Attending a Rockwell Automation event is the first step toward discovering how the latest innovations can have a meaningful impact on your business objectives and identifying new opportunities to help keep you ahead of the competition.

Take advantage of an upcoming Rockwell Automation event to learn more about how you can use technology as a competitive advantage to get your products and services to market faster, reduce costs, use power and plant-floor assets, and minimize the risks in your manufacturing environment.

Rockwell Automation Events & Webinars

Support

Leverage tools and downloads to design and maintain industrial applications.

To use Rockwell Automation’s products effectively, it is important that you have the necessary product information, tools, and support. Here you can find technical documentation, a software download center, product selection and configuration, and Proposal Work Builder.

Product Selection and Configuration

Let's Talk Allen-Bradley by Rockwell Automation

Ready to learn more about product and service options available to your company? Contact us at [email protected] or call 800-333-3122. Or submit your specific request below.