Why Mechatronics Is Essential in Modern Manufacturing

Key impacts of mechatronics:

- Automation: Mechatronic systems can reduce dependence on manual labor, operate around the clock and ensure consistency.

- Precision: Utilizing highly accurate components is a defining aspect of mechatronics and helps eliminate human error from the production equation.

- Quality: Mechatronics not only identifies defects in real-time but can also resolve the issue, reducing costly rework or expensive product recalls.

- Flexibility: Manufacturers need to adapt quickly to meet diverse and evolving customer demands; mechatronics can enable quick prototyping and rapid reconfiguration of production lines when necessary.

How Mechatronics Is Shaping the Future of Manufacturing

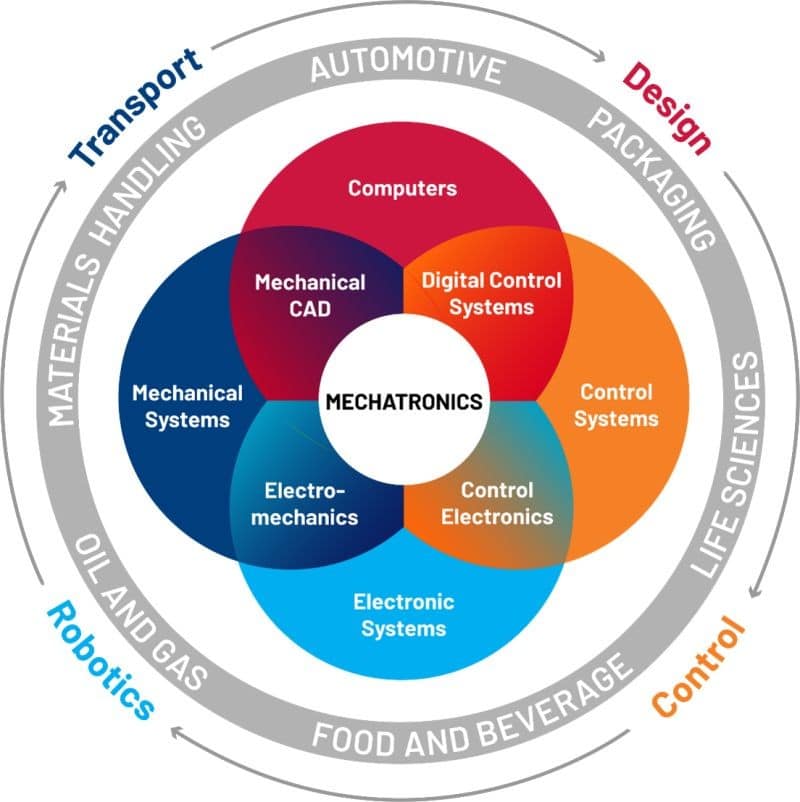

Mechatronics combines the best aspects of multiple engineering disciplines – mechanics, electronics, software and control systems (and more) – to create a more cohesive and reliable system for designing and building products. By integrating these fields, mechatronics creates simpler, smarter systems that can sense and interact with their environment, providing a complete solution to complex engineering problems. It is highly focused on automating processes, oftentimes utilizing robotics and incorporating sensors, actuators and microprocessors to perform complex tasks.

Some examples of how mechatronics is used, include:

- Manufacturing – Used to design and operate complex machines that can perform multiple tasks with high precision and accuracy.

- Automotive industry – Used to design and manufacture advanced systems such as self-driving cars, electric vehicles and advanced driver assistance systems (ADAS).

- Medical industry – Used to design and develop medical equipment such as surgical robots, prosthetics and medical imaging devices.

When manufacturers implement mechatronics, they can:

- Increase efficiency and productivity

- Reduce downtime and maintenance costs

- Improve product quality and consistency

- Automate repetitive or hazardous tasks

- Speed up production changeovers

- Allow for remote monitoring and control

- Expedite design-to-market time

Featured Manufacturers for Mechantronics

Unlocking Efficiency, Safety & Flexibility with Mechatronics from Rockwell Automation

In today’s competitive industrial landscape, manufacturers are constantly seeking ways to enhance efficiency, reduce costs, and maintain high stand [...]

Read MoreMechatronics Technology from Rockwell Automation Helps Manufacturers Keep Pace with Modern Consumer Demands

Consumer expectations are changing, so manufacturers must respond to the growing demand for a wider variety and more personalized products. Legacy equ [...]

Read More