OEMs: Build Smarter Machines & Stand Out from Your Competition

Agilix Solutions partners with Rockwell Automation to help OEMs compete and win in demanding markets. Together, we give OEMs differentiated machine capabilities while delivering measurable, margin-driving results for end users.

Agilix Solutions partners with Rockwell Automation to help OEMs compete and win in demanding markets. Together, we give OEMs differentiated machine capabilities while delivering measurable, margin-driving results for end users.

Smart machine solutions from Agilix and Rockwell Automation focus on:

- Speed – Accelerate design cycles and virtually commission systems using digital design tools

- Intelligence – Extend intelligence throughout electrical panels for faster builds and smarter operation

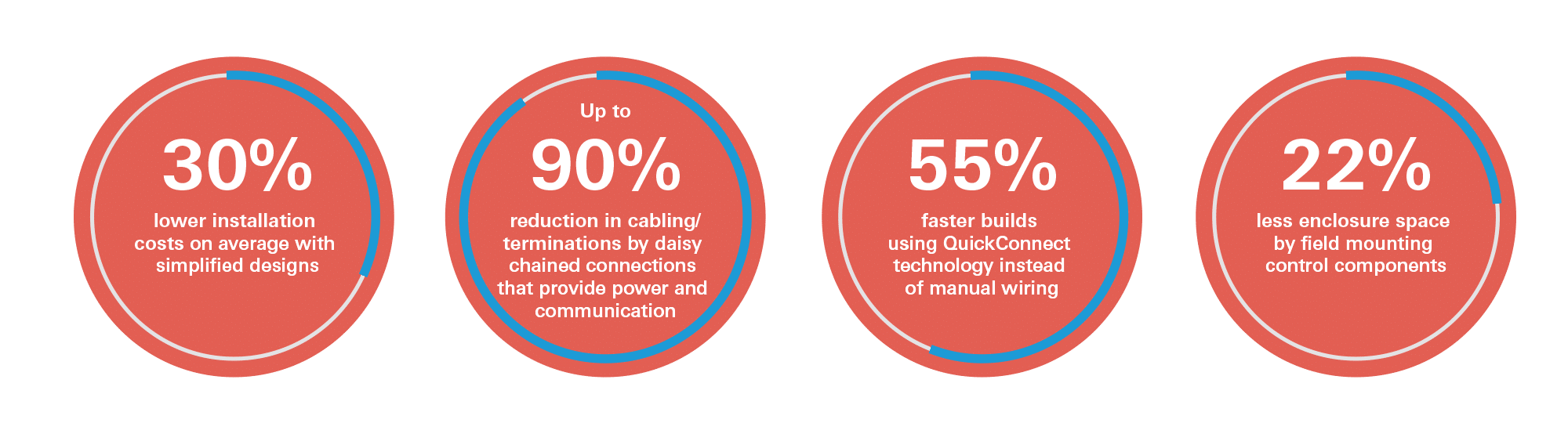

- Cost Efficiency – Reduce machine costs while increasing flexibility and speeding installation and startup through decentralized design

- Flexibility – Centralize flexible data management to unlock the full value of data and enable future-ready machines and equipment

Differentiating features provided by Rockwell Automation’s smart machine technologies include:

As a result, OEMs are better positioned to meet evolving customer expectations – particularly the increasing demand for data and the flexibility to adapt and scale operations. Ultimately, smarter machines lead to more satisfied customers, stronger relationships and improved profitability for all stakeholders.

How OEMs Help Manufacturers Unlock the Value of Their Data

Smart machines generate vast amounts of data, but turning that data into meaningful insights is the real challenge. To meet evolving end-user expectations, OEMs must deliver machines that seamlessly convert raw data into actionable intelligence that improves operational efficiency.

At the same time, a growing skills gap is affecting manufacturers across the industry. To keep operations moving forward, manufacturers are increasingly relying on OEMs to expand their role beyond machine delivery – providing value-added services throughout the machine lifecycle, including training, maintenance and consultative support.

Rockwell Automation’s DataReady solutions help to solve these problems by enabling a data foundation that can empower machines to provide value faster while still being flexible in the event of future changes in demand.

Using The Power of Data to Develop Smarter Machines

DataReady solutions from Rockwell Automation and Agilix Solutions enable OEMs to design machines that organize and structure data into consistent information models. This machine-level data can then be easily used to provide real-time insights at the equipment level and can be seamlessly integrated with other systems in the cloud, without requiring prior knowledge of how the information will be used in the future.

Data can then be shared from the machine and made available for use with virtually any external application. With this foundational capability in place, OEMs can unlock the power of data while maintaining the flexibility to introduce new components, revisit designs or modify applications to fit their unique needs.

Simplify Your Path to More Valuable Machine Designs

Manufacturers are demanding that their machines do more, but it can be difficult or impossible to address an expanding list of requirements with rigid designs. Our On-Machine™ solutions make it possible to simplify your machines, while enabling them to become more flexible and modular than ever. Using this breakthrough technology. you can unlock creative and unique equipment solutions by reducing or eliminating centralized enclosures and designing machines that are easier to diagnose and repair.

Unlock Value Through Modern Panel Design

An optimized control panel is an important part of helping your customers achieve compliance, remove barriers to productivity and improve overall equipment effectiveness (OEE). It is also critical for delivering reliable machines that best make use of valuable floor space. Using our panel optimization solutions, you can bring new levels of intelligence and innovation into your designs. With compact profiles, more reliable connections and seamless access to real-time data, these technologies can help you accelerate time to market, reduce risk and increase the profitability of your offering.

Get more from your machines with a technology that supports:

- Up to an 80% reduction in wiring time

- Up to a 50% reduction in testing time

- Up to a 30% reduction in project engineering time

Resources

Unlocking the Full Value of Industrial Data Starts at the Machine Level

Across manufacturing, the pressure to operate faster, leaner, and more intelligently continues to intensify. Nearly every manufacturer recognizes thi [...]

Read MorePredictive Maintenance: The Smart Financial Advantage Manufacturers Can’t Afford to Ignore

Production volume and product quality are table stakes in today’s modern manufacturing environment. The real competitive advantage comes from opera [...]

Read MoreHighlights from Automation Fair 2025: Rockwell Automation Innovations That Caught Our Attention

Automation Fair 2025 brought together thousands of professionals from across the industrial world, and as always, Rockwell Automation delivered an im [...]

Read More