Modern manufacturing success is built on the strength of its industrial network. As smart manufacturing, automation, and data-driven decision-making become the norm, your network must be designed for maximum uptime, visibility, and scalability.

Yet, many manufacturers still operate with networks that have evolved through years of piecemeal additions and reactive fixes. This results in a fragmented infrastructure that lacks security, visibility, and the ability to grow. At Agilix Solutions, we help simplify the complexity—empowering you to build a secure, modern, and scalable industrial network that supports both current operations and future innovation.

Enterprise vs. Plant Networks: Understanding the Difference

Enterprise Networks

These networks support business operations such as email, ERP systems, HR, and communication tools. While essential, enterprise network downtime typically doesn’t halt production.

Plant Networks

Plant networks drive real-time control and automation. When they go down, production stops—impacting safety, efficiency, and revenue. These networks require ultra-reliable designs, minimal latency, and robust security protections to ensure operational continuity.

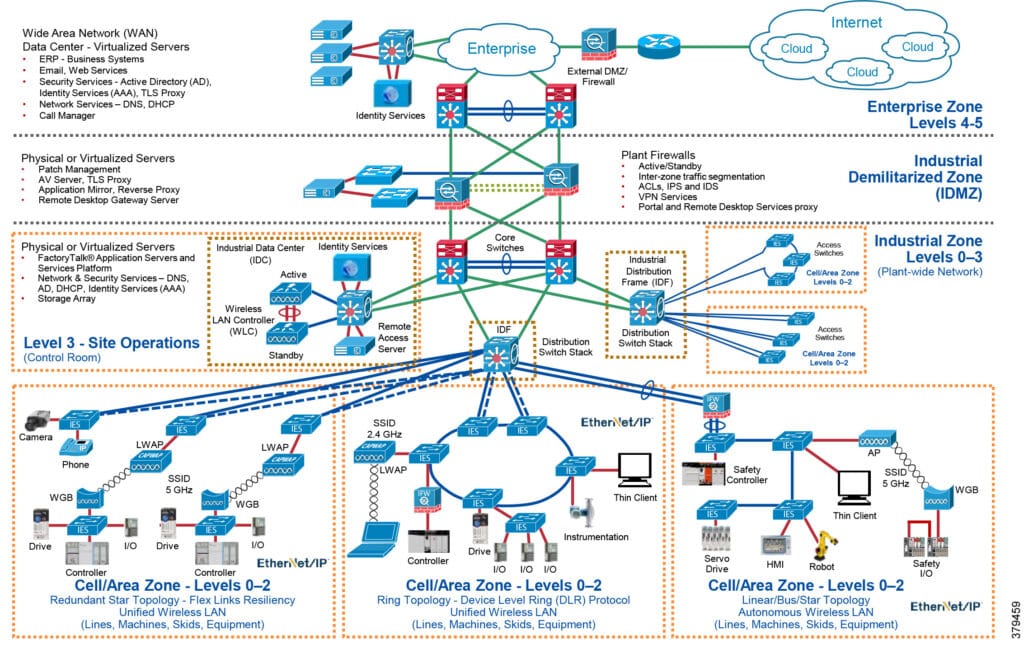

CPwE: The Gold Standard in Industrial Network Design

Converged Plantwide Ethernet (CPwE) is an architectural approach that integrates IT (Information Technology) and OT (Operational Technology), ensuring end-to-end visibility, segmentation, and security. Developed in collaboration by Cisco and Rockwell Automation, CPwE supports scalable, secure networks that can evolve with your business.

Key benefits of CPwE:

- Network segmentation for enhanced security and performance

- Redundancy and failover to minimize downtime

- Industrial firewalls and the Industrial Demilitarized Zone (IDMZ) to protect against cross-contamination between plant and enterprise systems

- Standardized use of Ethernet/IP and TCP/IP protocols to unify systems

With CPwE, IT and OT teams work in tandem to design, deploy, and maintain resilient infrastructure across both plant and enterprise networks.

Future-Ready Design Starts with the End in Mind

At Agilix Solutions, we don’t just connect devices—we proceed with purpose. Our approach begins by understanding your plant’s long-term goals. We map out your future state , resulting in a network architecture that scales as you grow, without sacrificing uptime or security.

Our engineers specialize in network segmentation, redundancy planning, secure remote access, and industrial cybersecurity. This ensures your network is not only compliant with today’s best practices but ready to embrace technologies like AI, edge computing, and predictive analytics.

Why Partner with Agilix Solutions?

At Agilix Solutions, we bring decades of hands-on experience supporting manufacturers across the United States. Our team specializes in both IT and OT network infrastructure, providing the technical expertise needed to bridge the gap between enterprise systems and plant-floor operations.

Our engineers hold leading industry certifications, including CCNA, CCNP, and CISSP, reflecting our deep knowledge of network design, security, and best practices. We also maintain strong partnerships with top technology providers like Cisco, Fortinet, HPE, Rockwell Automation, and others—ensuring we offer the right solution for your environment.

Whether you’re modernizing legacy systems, building out new facilities, or securing your OT network from cyber threats, Agilix Solutions is your trusted partner for scalable, secure, and future-ready industrial network design.