Last year we announced the opening of the Southwire SIMpull® Demo Center at Agilix Solutions’ St. Louis headquarters. Since then, we’ve hosted many customers looking to get hands-on experience with Southwire’s game changing SIMpull Solutions product line, designed to completely transform the process of wire pulling on the jobsite.

Today, we want to feature some of the most prominent products the Demo Center allows us to showcase and explain how these difference makers can be deployed to help your team do more work faster and with fewer hands.

QWIKrope® Pulling Rope

QWIKrope® Pulling Rope

QWIKrope® is an innovative, high-performance pulling rope from Southwire that is UV resistant and lightweight, while offering ultra-low stretch for all your feeder and circuit wire pulling needs. It’s constructed of ultra-high weight polyethylene fibers, which translates to a 12-strand, single braided 9/16” pulling rope with a breaking strength of 32,000 lbs. in feeder conductor pulls. For circuit wire pulls, there’s a 1/8” option with a breaking strength of 1,100 lbs. and a ¼” option with a breaking strength of 7,500 lbs.

QWIKrope features dual factory-installed pulling eyes and doesn’t absorb water, meaning you don’t have to worry about rope rot. When tested against traditional pulling ropes, it delivers a 24% reduction in the coefficient of friction.

SIMpull CoilPAKTM Wire Payoff

SIMpull CoilPAKTM Wire Payoff

Say goodbye to bulky spools and the exhausting and time-consuming setup process that comes with them on branch circuit installations. SIMpull® CoilPAKTM Wire Payoffs increase both safety and productivity by reducing the physical effort associated with material handling, pulling wire out of packaging, and running it through conduit. Its stationary package is designed specifically to reduce pulling effort and the wire is housed in a SIMpull NoLube® jacket that further reduces pulling tension. There’s no more broken spools or spool over-turn, as the space-saving multi-wire CoilPAK payoffs deliver greater efficiency with less handling.

MAXIS® Cable Pullers

MAXIS® Cable Pullers

The MAXIS® line of cable pullers from Southwire is all about efficiency. The pullers can be set up and ready to pull in two minutes by just one person. They quickly adapt from underground pulls to overhead pulls and vice versa. While for most pulls MAXIS pullers do not need to be bolted to the ground, they do offer the option. They can also be anchored to most trucks’ 2” receiver hitch, making them versatile enough to adapt to nearly any wire pull.

Southwire offers their revolutionary MAXIS® cable puller in 3K (3,000-lb peak pulling force) and 6K (6,000-lb. peak pulling force) models. Both models can be purchased in motorized and non-motor versions.

SIMpull BarrelTM Cable Drums

SIMpull BarrelTM Cable Drums

Moving, setting up, and pulling circuit wire spools can be physically challenging. Spools are bulky, they break easy, and using them often results in partial lengths that are difficult to store or become scrap. The end result is wasted physical effort, manpower, and materials. Southwire’s SIMpull BARRELTM Cable Drum is designed to reduce the physical effort associated with material handling, setup, and pulling. It can contain up to seven parallel conductors per barrel, increasing productivity and reducing potential for injury while eliminating broken spool risk and cutting down material waste. The wire is housed in a SIMpull NoLube wire jacket which, combined with the BARREL’s stationary package design, drastically reduces pulling tension.

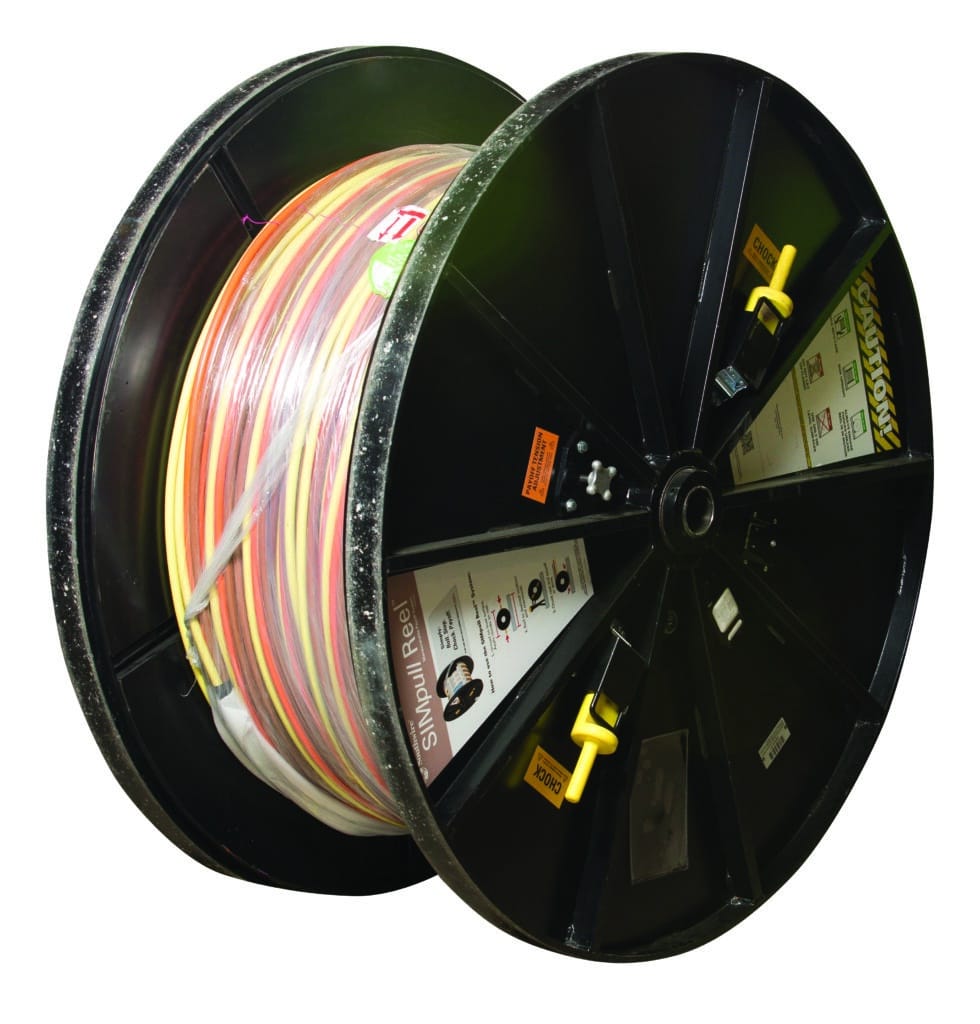

SIMpull Reels and Flanges

SIMpull Reels and Flanges

Feeding cable into buildings is a lot of work. The setup alone causes all sorts of challenges, and the process requires excessive labor, equipment, tools, effort, and time. Southwire’s SIMpull Reel system changes all of that. Each SIMpull Reel can safely transport up to 6,000 pounds of cable yet fit through a standard 38” door. Even more impressive, it’s designed to be movable by a single person directly to the spot of the pull with no additional equipment required. You save time and money before the job even begins. When you’re ready to start the pull, the SIMpull reel allows you to combine up to five wires of individually colored conductors for up to four pulls on a single reel, depending on cable size and pull length.

SIMpull Flanges

See the Southwire Difference for Yourself

See the Southwire Difference for Yourself

We’ve yet to have a customer visit our Southwire SIMpull Demo Center and leave less than impressed with the capabilities of the entire fleet of SIMpull Solutions. With tightening labor markets and the always intensifying pressure to increase efficiency and impact the bottom line, you owe it to yourself to see the value and power of these modern innovations in wire pulling. Reach out to your Account Manager to schedule a visit to our St. Louis headquarters at 2023 Westport Center Dr. to experience it for yourself.

QWIKrope® Pulling Rope

QWIKrope® Pulling Rope SIMpull CoilPAKTM Wire Payoff

SIMpull CoilPAKTM Wire Payoff MAXIS® Cable Pullers

MAXIS® Cable Pullers SIMpull BarrelTM Cable Drums

SIMpull BarrelTM Cable Drums SIMpull Reels and Flanges

SIMpull Reels and Flanges See the Southwire Difference for Yourself

See the Southwire Difference for Yourself