If you have ever had to troubleshoot or commission your plant’s variable frequency drives (VFDs), you’ve likely wrestled with finding the correct parameters to get back up and running. In this blog we will explore how Rockwell Automation’s Connected Components WorkbenchTM is eliminating the hassle and headache commonly associated with drive startup and troubleshooting.

What is Connected Components Workbench (CCW)?

Connected Components Workbench (CCW) is a software product from Rockwell Automation designed to simplify machine development. The software is a part of Rockwell Automation’s Integrated Architecture® system. It provides device configuration, controller programming, and integration with a human machine interface (HMI) editor.

The software is offered in both Standard and Developer Editions. The Standard Edition features a common, easy-to-use configuration and programming software for a Rockwell Automation Micro Control System. It also includes a demo version of the Micro800 Simulator. The Standard Edition is FREE to download on Rockwell Automation’s website. The Developer Edition offers everything available in Standard, as well as the full Micro800 Simulator and Archive Manager. You also get extensive Micro800 controller programming capabilities for an enhanced user experience in the Developer Edition.

There are numerous advantages to implementing CCW into your machine architecture. First and foremost, you’ll reduce development time, as the single Connected Components Workbench software solution can be used to configure multiple devices for standalone machines. It also allows you to easily connect to devices through various serial and network options. The latest release of the software introduced the opportunity to share code between Connected Components Workbench and Studio 5000 Logix Designer software simply using copy and paste. Users are now also able to capture, view, and analyze real-time data with PowerFlex® drives and Micro800 Trending.

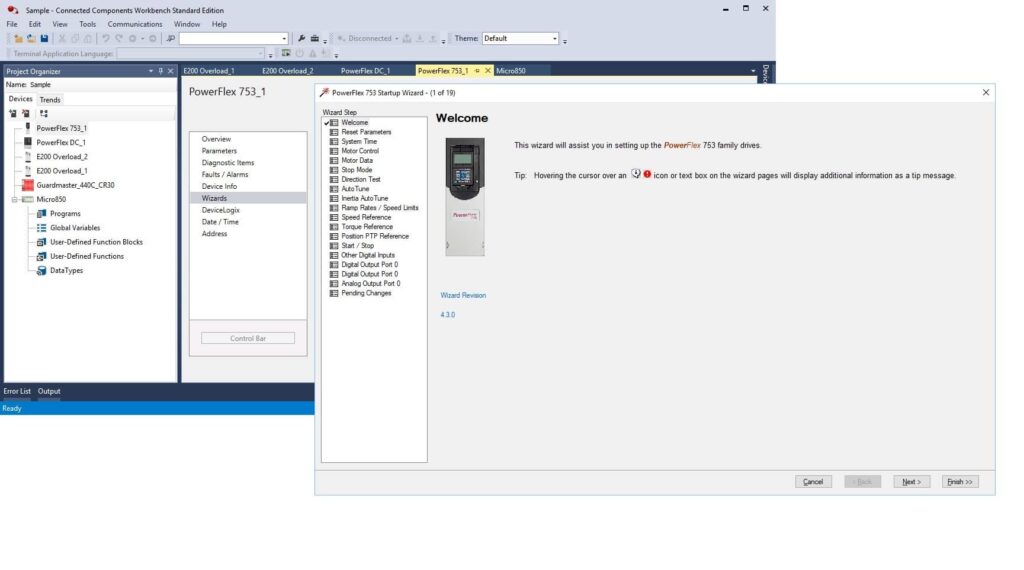

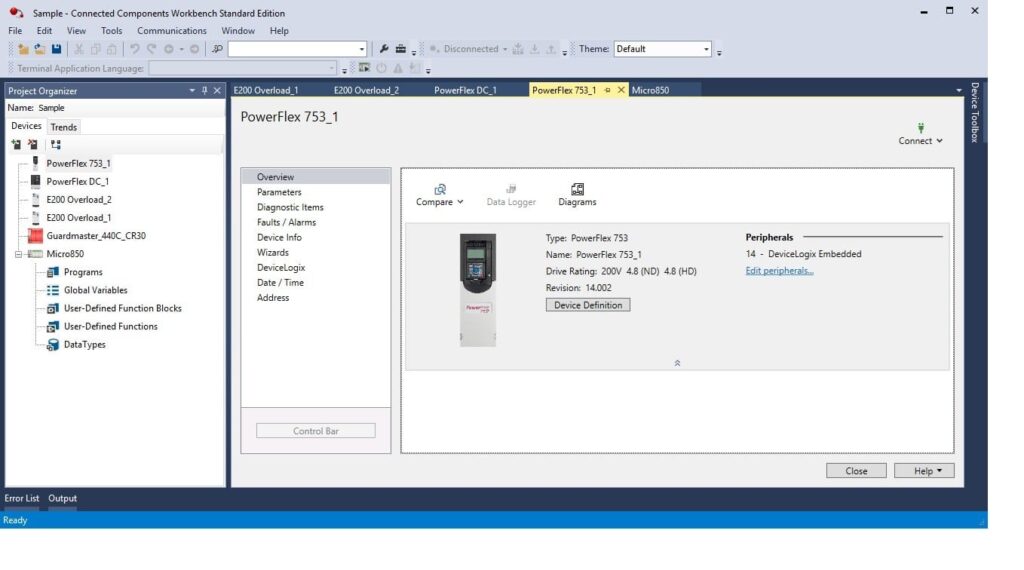

Startup and Application Wizards Simplify Configuration

The genius of the CCW software is in how it simplifies otherwise complex tasks. For starters, CCW feels familiar to new users because it uses a common, simple configuration to reduce development time. Configuring PowerFlex® drives is made easy thanks to software wizards that guide the process. You’re prompted for all the required information to get your drive up and running quickly. Drive programs can be saved for future use, and you can see and modify parameters remotely, or display multiple parameters at the same time. Device firmware is simple to update from project organizer, without ControlFLASHTM.

Connectivity also comes with options. Users can connect to devices using USB, EtherNet/IP and serial communications.

Speaking of Connectivity…

Agilix Solutions has what you need to get the most out of Connected Components Workbench. The 1203-USB Programming Cable simplifies the communications interface between your computer and PowerFlex drives. When used with either version of the CCW software, this USB to serial converter will provide a connection to DPI for PowerFlex 7-Class drives, PowerFlex 750-Series drives, and PowerFlex DC drives, as well as DSI for PowerFlex 4-Class drives, PowerFlex 520-Series drives, and Kinetix 3 drives.

Agilix Solutions brings a wealth of experience and expertise to help you get the most out of the Connected Components Workbench software. For an in-depth walkthrough, check out this video from Agilix Solutions Power Product Managers Chris Rapp and Charles Hummer. If you need additional support, we’re here to help. Contact your local Agilix Solutions location to get the answers you need.

Agilix Solutions is only authorized to distribute Allen-Bradley, Rockwell Software and Rockwell Automation products in select geographic areas. Contact us for more information.